Information Details

Lean production is the process of transforming the production system through changes in system structure, personnel organization, operational methods, and market supply and demand. It enables the production system to quickly adapt to the constantly changing needs of users and streamline all useless and redundant things in the production process, ultimately achieving the best results in all aspects of production, including market supply and sales

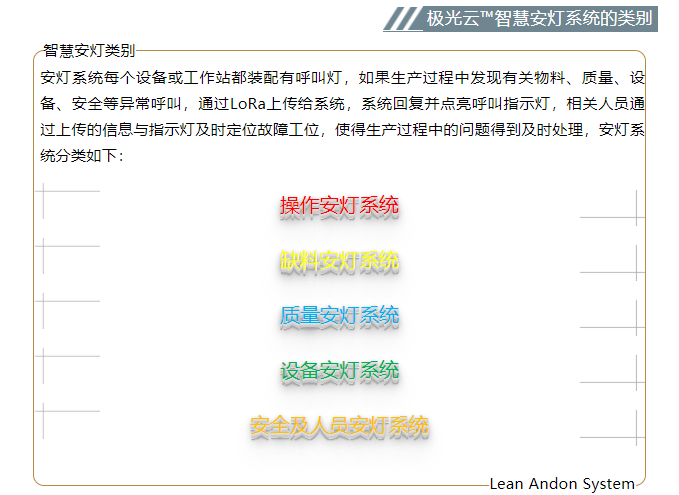

The practice of lean production has been around for half a century since the Japanese began. Compared to the mass production methods in the United States, lean production has reduced human resources (including product development, production systems, and other departments in the factory) to 50%, reduced new product development cycles to 50%~66%, reduced factory space occupancy to 50%, reduced finished product inventory to 25% of the average inventory level in mass production factories, and increased product quality by three times... It has brought about a quantitative improvement and transformation in enterprise production efficiency. Therefore, lean factories have more precise and detailed requirements in 5S, just in time production, value stream analysis, waste elimination, continuous improvement, error prevention, comprehensive preventive maintenance, rapid switching, team building, and employee participation. The smart lighting system has become an important management tool for information management in lean factories.

The practice of lean production has been around for half a century since the Japanese began. Compared to the mass production methods in the United States, lean production has reduced human resources (including product development, production systems, and other departments in the factory) to 50%, reduced new product development cycles to 50%~66%, reduced factory space occupancy to 50%, reduced finished product inventory to 25% of the average inventory level in mass production factories, and increased product quality by three times... It has brought about a quantitative improvement and transformation in enterprise production efficiency. Therefore, lean factories have more precise and detailed requirements in 5S, just in time production, value stream analysis, waste elimination, continuous improvement, error prevention, comprehensive preventive maintenance, rapid switching, team building, and employee participation. The smart lighting system has become an important management tool for information management in lean factories.

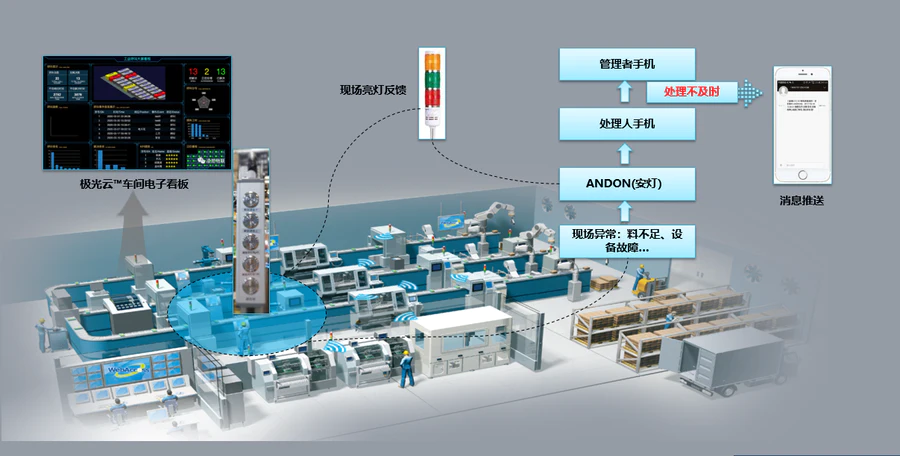

Aurora Cloud ™ Value and Case Study of Smart Security Lamp Application

Lean Andon System

AND

5.1

happy International Workers ' Day

Related information

-

![]()

-

![]()

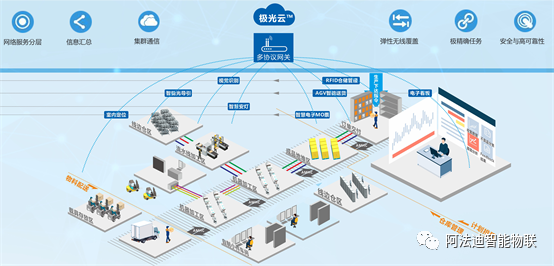

AIOT empowers intelligent digital "smart" internal logistics - Afadi Aurora Cloud ™ Factory Supply Chain IoT Open Platform Jiangcheng Debuts

-

![]()

Dongfeng Shenlong: Manufacturing Management Department actively explores intelligent logistics to drive intelligent manufacturing DMAF ACTIVELY EXPLORES SMART LOGISTICS TO DRIVE INTELLIGENT MANUFACTORY

-

![]()

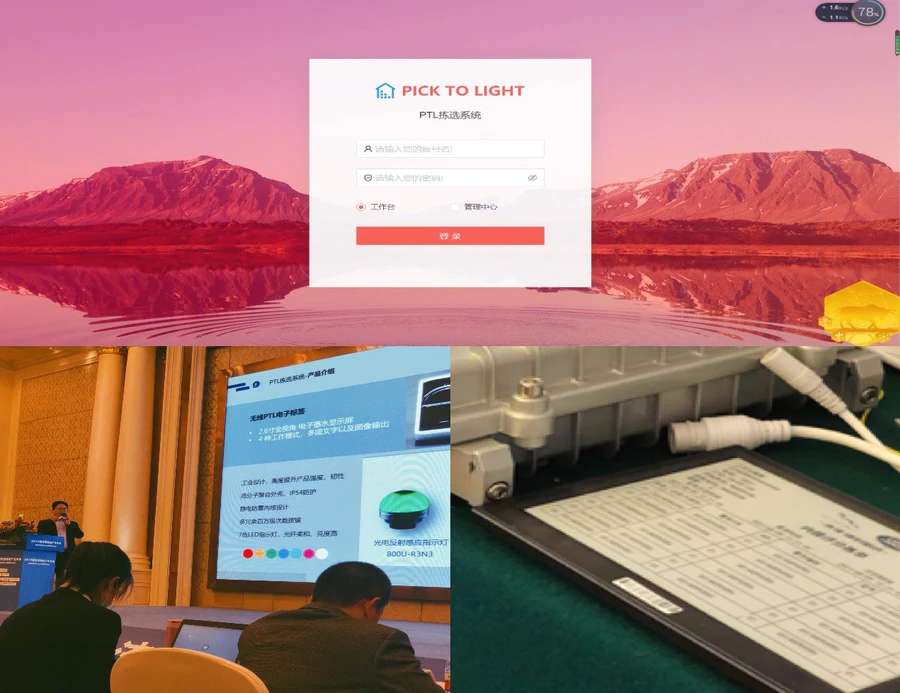

Aurora Cloud ™ Application of Wireless PTL in SPS Picking

-

![]()

Aurora Cloud's Agile Supply Chain Debuts at the 2021 China Smart Logistics Industry Annual Conference and Automotive Intelligent Manufacturing Digitalization and Smart Logistics Summit

-

![]()

Wireless PTL (Pick To Light) electronic tag picking solution

-

![]()

Application of Smart Safety Lamp in Lean Production

-

![]()

Empowering the digitalization of automotive business, Afadi's "AIOT Supply Chain+" solution made a brilliant appearance at the 8th Automotive Intelligent Manufacturing Advanced Technology Summit in 2021

-

![]()

Carbon Neutrality: Application of Electronic MO Tickets in Paperless Green Factory Construction

-

![]()

【 Rooting down, growing up 】 Afadi IoT departs in 2021