Information Details

Customer Status:

The manufacturer's current small item shelf storage area is densely packed with locations and items, with each sorter responsible for sorting tasks for multiple corresponding shelves. The customer needs to transform the intelligent material rack to achieve lighting guidance, allowing workers to operate in a "foolproof" manner, achieve fast picking, low error rates, ensure timely and accurate delivery, and meet the efficient production pace of the production line, ensuring the continuous stability of production.

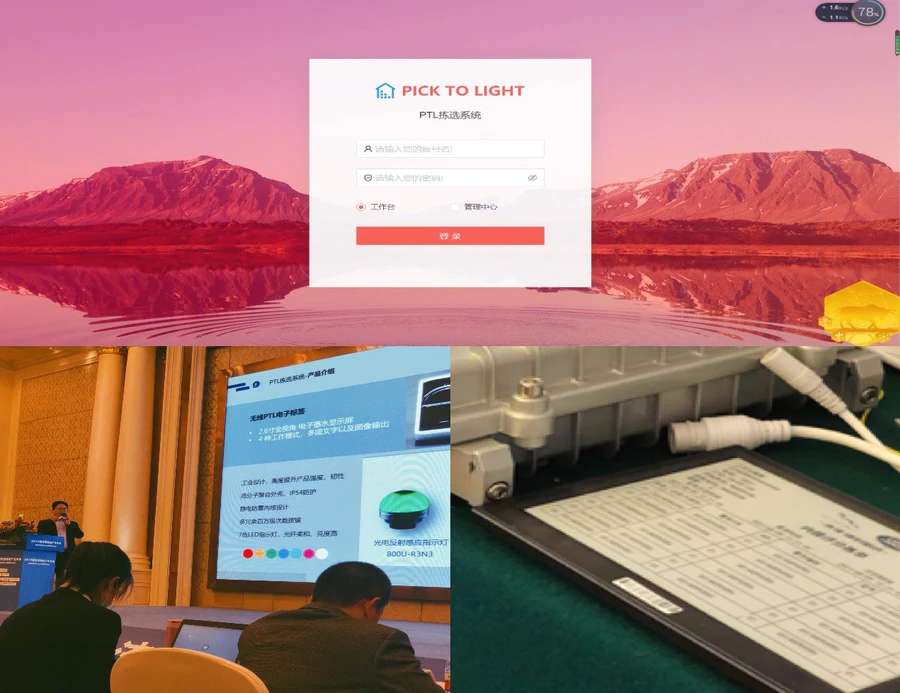

Aurora Cloud ™ Wireless PTL function:

Display - Tags can display information such as picking name, quantity, specifications, etc., using wireless communication and battery power supply

Power Supply - The tag supports low battery alarm, displays a low battery icon on the screen, and the backend can query the battery level. The battery can be used for more than 1 year

Installation - The label can be fixed on the shelf with accessories

The data PTL tag server can seamlessly integrate with MES systems/WMS and other systems

Aurora Cloud ™ Wireless PTL solution:

Scan the QR code of the warehouse receipt, and the PTL picking system will automatically retrieve the warehouse task from the WMS system

According to the established shelving rules for matching incoming materials, personnel first scan the material number, and the light picking system automatically matches the warehouse location (it is necessary to bind the material to the warehouse location); The lighting picking rack system will send matching warehouse location information to electronic tags for lighting prompts

The homework personnel locate the warehouse location and scan the material barcode and warehouse location code for loading (unloading); Matching is correct, the upper (lower) shelf is completed, and the storage location light is turned off

The intelligent lighting system automatically sends inventory information back to the WMS system after completing the upper (lower) shelves

Aurora Cloud ™ Product composition of wireless PTL solution:

PTL Server: Implement data exchange with WMS and control the workflow of electronic tags

AP: Send tag data from PTL server to electronic tags wirelessly

Key responder: Obtain key status information of tags or lighthouses

Wireless lighthouse: indicates the picking status by lighting up

Wireless tag: indicates picking status through lighting and screen display

Handheld gun: Scan the picking list and notify the user that the server will send the picking information

Aurora Cloud ™ Value advantages of wireless PTL:

MES/WMS seamless integration, simplified order processing

Paperless management visual wall, making line edge warehouse decisions more intelligent

Wireless PTL has many advantages such as simple shelf renovation, fast construction, and low cost

Related information

-

![]()

-

![]()

AIOT empowers intelligent digital "smart" internal logistics - Afadi Aurora Cloud ™ Factory Supply Chain IoT Open Platform Jiangcheng Debuts

On July 14th, the 7th China Automotive (Parts) Intelligent Production&Lean Logistics Collaborative Development Forum was organized and held in Wuhan. The summit was hosted by Shanghai Huiwen Supply Chain Management Co., Ltd. and co organized by Dongfeng Motor Group Co., Ltd. Technical Center and Dongfeng Corporation Old Science and Technology Association Technical Center Federation -

![]()

Dongfeng Shenlong: Manufacturing Management Department actively explores intelligent logistics to drive intelligent manufacturing DMAF ACTIVELY EXPLORES SMART LOGISTICS TO DRIVE INTELLIGENT MANUFACTORY

On August 24th, Shanghai Afadi Intelligent IoT Technology Co., Ltd. gave a lively lecture on smart logistics with the theme of "Agile Supply Chain Solutions" in Conference Room 206 of Dongfeng Shenlong General Assembly Building. Afadi's technical engineer provided a detailed account of the blueprint, framework, concept, and successful implementation cases of the smart factory -

![]()

Aurora Cloud ™ Application of Wireless PTL in SPS Picking

Automobile final assembly is the process of assembling various components of a car together, and it is the place where the entire car can be seen throughout the entire manufacturing process. High tempo assembly line planning requires the rational planning of the process flow, information flow, and logistics of automobile assembly with intelligent manufacturing thinking, achieving unified, coordinated, advanced, and low -

![]()

Aurora Cloud's Agile Supply Chain Debuts at the 2021 China Smart Logistics Industry Annual Conference and Automotive Intelligent Manufacturing Digitalization and Smart Logistics Summit

On December 22, 2021, the 2021 China Smart Logistics Industry Annual Conference and the Automotive Intelligent Manufacturing Digitalization and Smart Logistics Summit were grandly held in the mountainous city of Chongqing. Afadi Intelligent IoT and Aurora Cloud ™ Innovative products such as reliable data collection and display based on wireless technology, wireless electronic paper systems, wireless PTL systems, etc -

![]()

Wireless PTL (Pick To Light) electronic tag picking solution

Customer status: The manufacturer's current small item shelf storage area is densely packed with locations and items, and each sorter is responsible for sorting tasks for multiple corresponding shelves. The customer needs to transform the intelligent material rack to achieve lighting guidance, allowing workers to operate in a "foolproof" manner, achieve fast picking, low error rate, and ensure timely and efficient delivery -

![]()

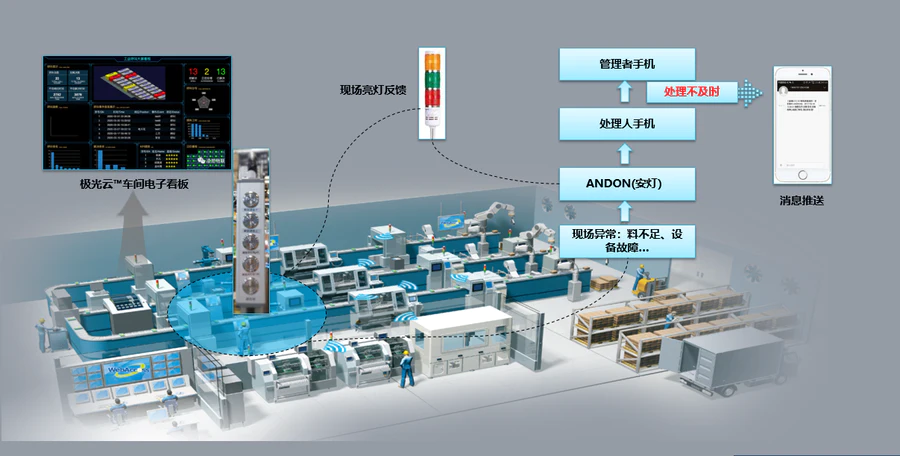

Application of Smart Safety Lamp in Lean Production

Lean production is the process of transforming the production system through changes in system structure, personnel organization, operational methods, and market supply and demand. It enables the production system to quickly adapt to the constantly changing needs of users and streamline all useless and unnecessary things in the production process, ultimately achieving the best results in all aspects of production, including market supply and sales -

![]()

Empowering the digitalization of automotive business, Afadi's "AIOT Supply Chain+" solution made a brilliant appearance at the 8th Automotive Intelligent Manufacturing Advanced Technology Summit in 2021

The 8th Automotive Intelligent Manufacturing Advanced Technology Summit 2021 was held in Tianjin to empower the digitalization of the automotive business. Afadi's "AIOT Supply Chain+" solution made a brilliant debut in digitalization. "Digital enterprises are connecting human and machine data, organizing and analyzing it, and improving the enterprise at all times" - by Guolian Stock -

![]()

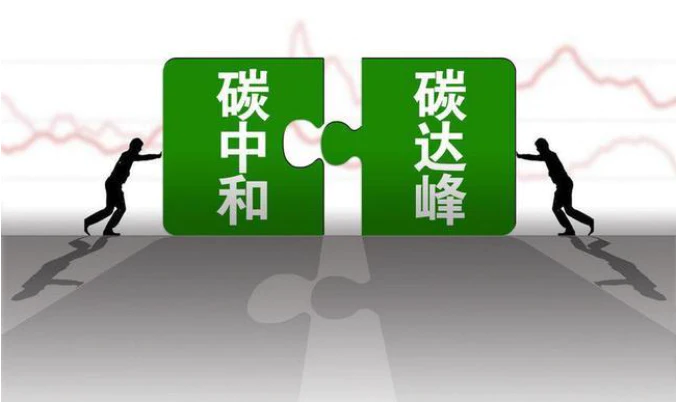

Carbon Neutrality: Application of Electronic MO Tickets in Paperless Green Factory Construction

Carbon Neutrality: Application of Electronic MO Tickets in Paperless Green Factory Construction Carbon neutrality brings new trends: "Strive to peak carbon dioxide emissions before 2030 and strive to achieve carbon neutrality before 2060." At the beginning of the 14th Five Year Plan, China set this 10-year commitment and further "8 -

![]()

【 Rooting down, growing up 】 Afadi IoT departs in 2021

Rooting down and growing up - Afadi IoT departs. On January 5, 2021, Shanghai Afadi Intelligent IoT Technology Co., Ltd. held a 2020 work summary conference in Hangzhou. Each center reviewed the work of the year 2020, looked forward to and planned for the work of 2021

contact information

-

electricWords: 0571-8813 6836

-

Phone: 0571-8813 9887

-

官网: https://www.alpha-rfid.com/

-

邮箱:info@alpha-rfid.com

-

![]()

Follow the subscription account

-

![]()

Follow Service Number

Copyright (C) 2020 Shanghai Afadi All Rights Reserved沪ICP备20016538号-1