Information Details

2021On December 22nd of the year2021China Smart Logistics Industry Annual Conference and Automotive Intelligent Manufacturing Digitalization and Smart Logistics SummitGrandly held in the mountainous city of Chongqing, Afadi Intelligent IoT brings Aurora Cloud ™ Innovative products such as reliable data collection and display based on wireless technology, wireless electronic paper systems, and wireless PTL systems were showcased at the summit. Xiao Hongyong, General Manager of Afadi Intelligent IoT, delivered a speech titled 'Aurora Cloud' ™ Speech on the Application of Agile Supply Chain Solutions in Lighthouse Factory.

The digital new economy era leads the innovation and transformation of digital industry.In 2019, the digitalization rate of production equipment in industrial enterprises above designated size was 47.1%, the CNC rate of key processes was 49.5%, the networking rate of digital equipment was 41%, and the popularization rate of digital R&D design tools reached 69.3%. Industry experts and committee members from China Equipment Management Association, Chongqing Municipal Bureau of Industry and Information Technology, China Equipment Management Association Smart IoT Technology and Equipment Development Promotion Center, Advanced Manufacturing Innovation Research Institute of the Ministry of Industry and Information Technology, Qingchang An Automobile Co., Ltd., Chengdu Lynk&Co, FAW Volkswagen, and other industries gathered to jointly explore the opportunities and challenges brought by the changes in the world economic landscape, as well as the strategy of innovation driven industrial enterprise development.

The standard and unified information model is the industrial Internet2.0The core technology of the system The series of scenario problems caused by opaque factory management, such as information silos, incomplete processes, weak object control, and poor interaction, have been addressed by numerous excellent manufacturers who, in line with the theme of "co creation, win-win sharing", shared intelligent solutions, implementation processes, and effect interpretations on site. The expert members of the "think tank" include AGV manufacturers, intelligent forklifts, intelligent logistics, and smart IoT enterprises, aiming to promote the automation of automobile production and manufacturingIntelligentizationUpgrade to digitalization and networking, accelerate innovation and transformation, and actively provide suggestions and recommendations.

Aurora Cloud™ Agile Supply Chain Innovation Application 1- Trusted Data Collection and Display Based on Wireless Technology

"Industrial IoT and energy Internet, this is a major development trend. Industrial IoT and energy Internet are developing from a chimney like construction mode to a platform based and shared direction. We are a shared network, and the final problem is the problem of centralization. How to solve the problem of trust, under this condition, we know that blockchain is the best way to solve trust. Among blockchain technologies, data sharing and security authentication are the most important landing values at present"(Associate Professor Yu Peng, Beijing University of Posts and Telecommunications)

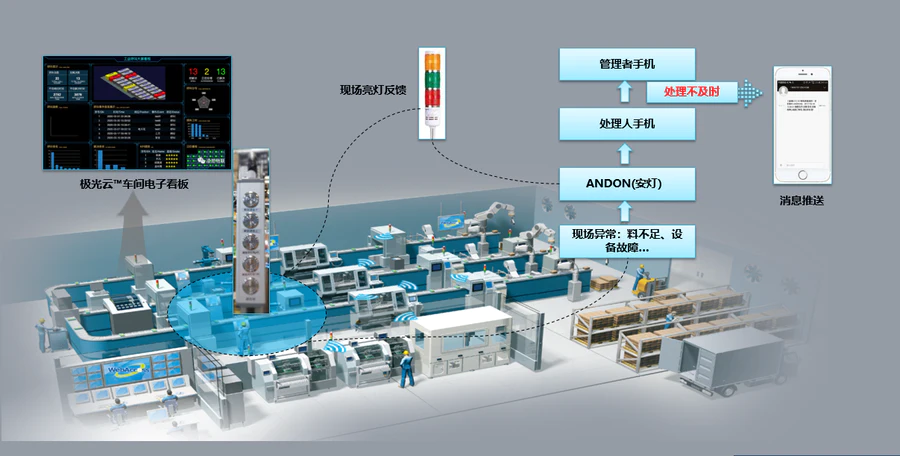

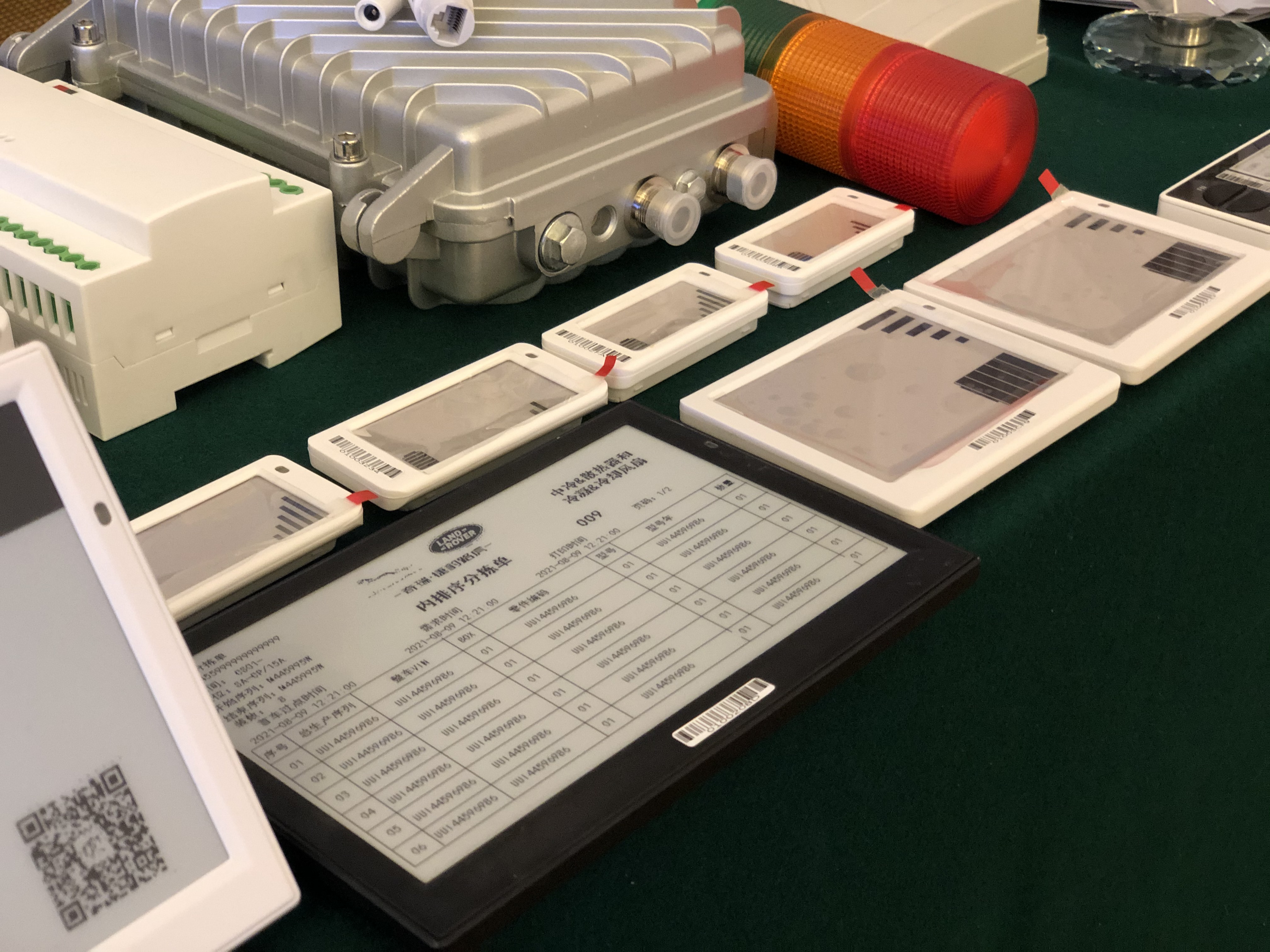

Integrating real-time indoor positioning, paperless display of materials and electronic tags, Aurora Cloud ™ The RFID trusted data+AGV+electronic tag solution can be applied to real-time intelligent management of materials and supplies in intelligent production workshops, including searching, outbound, inbound, and tracking. It guides AGV robots to correctly, quickly, and easily identify warehouse locations, accurately find goods, complete automatic outbound, and achieve collaborative operations between people, machines, and materials.

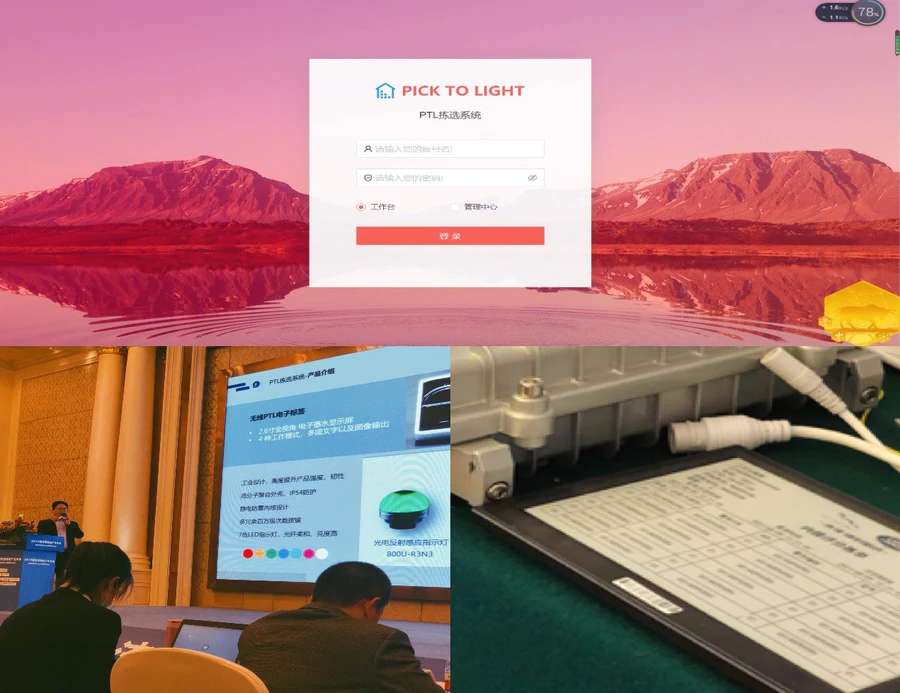

Aurora Cloud™ Agile Supply Chain Innovation Application 2- Wireless PTL System

Wireless PTL picking is an intelligent order picking system for warehouses and shelves based on wireless technology and ink screen display. The system includes what we call intelligent electronic tags, wireless base stations, and control systems. The picking requirements are sent to the control system through the management system, and the system lights up the location lights according to the order content as a guide to extract the goods. This method reduces a large amount of tedious paper documents, making homework easy and efficient, and improving the original work efficiency by 30%.

Summit silhouette:

Related information

-

![]()

-

![]()

AIOT empowers intelligent digital "smart" internal logistics - Afadi Aurora Cloud ™ Factory Supply Chain IoT Open Platform Jiangcheng Debuts

-

![]()

Dongfeng Shenlong: Manufacturing Management Department actively explores intelligent logistics to drive intelligent manufacturing DMAF ACTIVELY EXPLORES SMART LOGISTICS TO DRIVE INTELLIGENT MANUFACTORY

-

![]()

Aurora Cloud ™ Application of Wireless PTL in SPS Picking

-

![]()

Aurora Cloud's Agile Supply Chain Debuts at the 2021 China Smart Logistics Industry Annual Conference and Automotive Intelligent Manufacturing Digitalization and Smart Logistics Summit

-

![]()

Wireless PTL (Pick To Light) electronic tag picking solution

-

![]()

Application of Smart Safety Lamp in Lean Production

-

![]()

Empowering the digitalization of automotive business, Afadi's "AIOT Supply Chain+" solution made a brilliant appearance at the 8th Automotive Intelligent Manufacturing Advanced Technology Summit in 2021

-

![]()

Carbon Neutrality: Application of Electronic MO Tickets in Paperless Green Factory Construction

-

![]()

【 Rooting down, growing up 】 Afadi IoT departs in 2021